3D Printed Robotic Arm

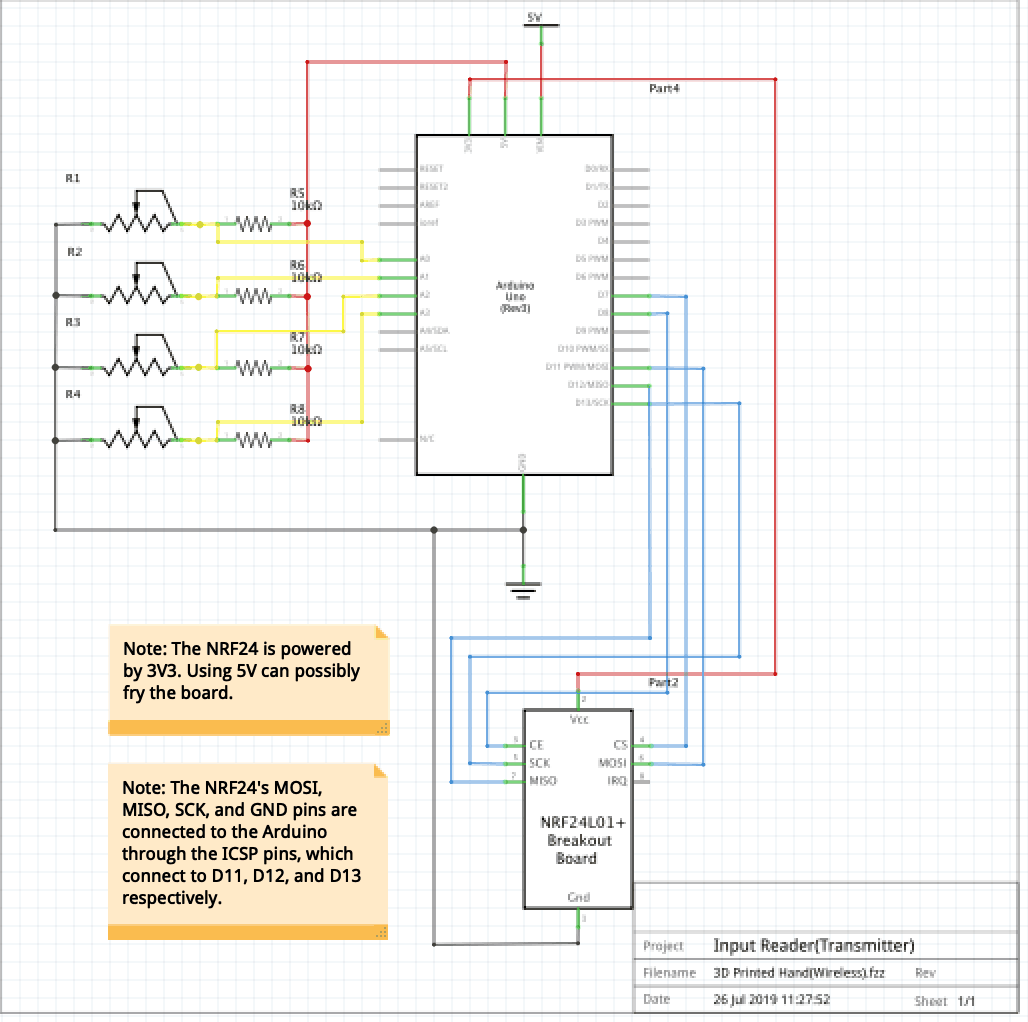

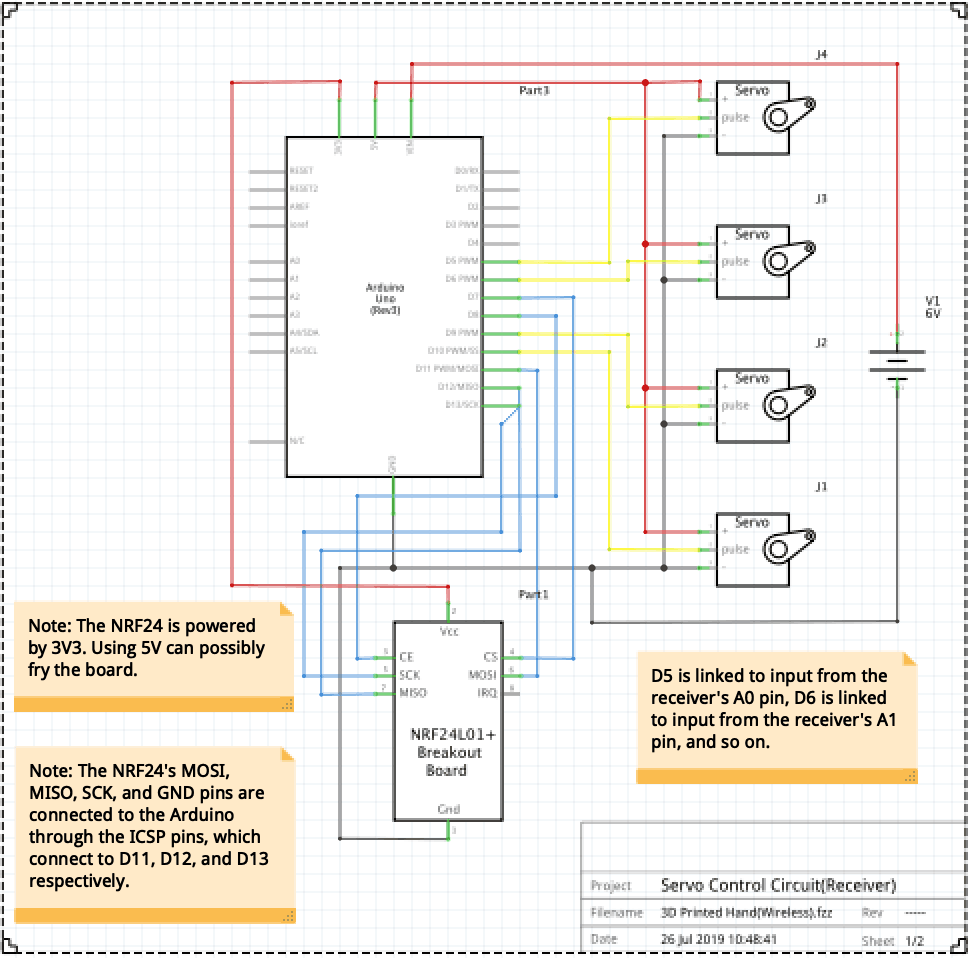

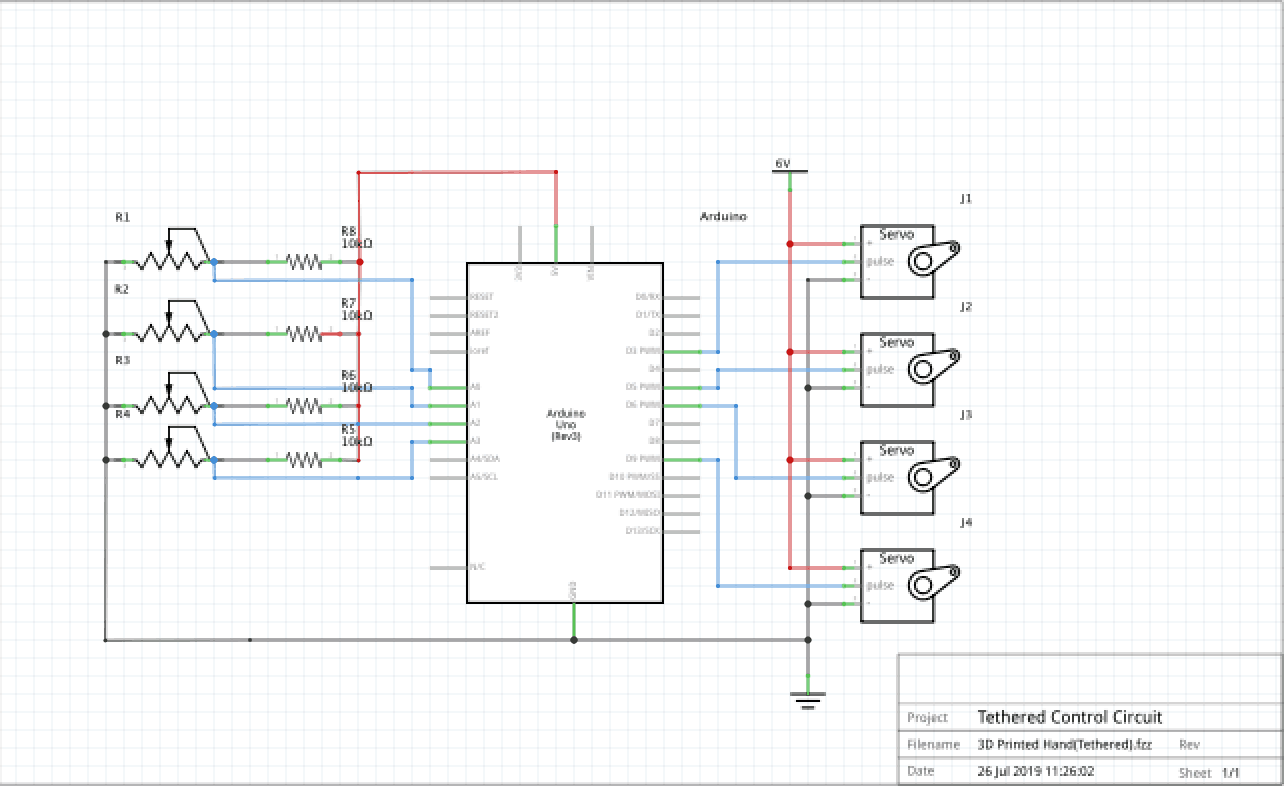

This is a 3D printed hand wirelessly controlled by a glove. The hand was assembled according to instructions on http://theroboarm.com/section1.html. I programmed one arduino to read input from the glove, and another to control the servo motors. Documentation is shown below.

Engineer

Qilin Y

Area of Interest

Computer Science

School

Abraham Lincoln HS

Grade

Rising Junior

Third Milestone

Watch my Demo Night presentation here!

#include <RF24.h>

#include <Servo.h>

#include <SPI.h>

const int numServos = 4;

const int measurementPins[] = {A0, A1, A2, A3}; // pins to connect to the flex sensors

const int resistanceRangeA[] = {530, 510, 575, 530};

const int resistanceRangeB[] = {770, 650, 740, 670};

int increment = 5; // rate at which to move the servos – increment° / 50 millis

const Servo servos[numServos]; // creates the array of servo controller objects

const int servoPins[] = {5, 6, 9, 10}; // pins to attach to the servos

// 5 : ring/pinky, 6: middle finger, 9: index finger, 10: thumb

int servoAngle[] = {0, 0, 0, 180}; // stores the current angle of the servos

int offsetAngle[] = {0, 0, 0, 180};//allows me to control the direction of the servos

const int cePin = 8; // chip enable

const int csnPin = 7; // chip select

RF24 radio(cePin, csnPin);

bool writePin = false; // whether the arduino is being used to write

const uint64_t pipeAddress = 0xF0F0F0F0F001; // commmon address between the two NRF24l01 boards

const int payloadSize = 8 * numServos; // 8 bits per sensor/servo

void setup() {

Serial.begin(9600);

radio.begin();

(writePin? setAsWriter() : setAsReader());

radio.setPALevel(RF24_PA_LOW);

}

void loop() {

if(writePin){ // if this is the transmitter

unsigned long output = 0; // variable that stores input

for(int i = 0; i < numServos; i ++){

long val = analogRead(measurementPins[i]); // read from a flex sensor

val = map(val, resistanceRangeA[i], resistanceRangeB[i], 0, 180) / (4 * increment); // maps raw output to servo rotation, rounded to reduce twitching

val *= 4 * increment;

val = abs(val – offsetAngle[i]);//flips servo rotation if offsetAngle[i] is 180

// makes sure val is in the correct range

if(val < 0) val = 0;

if(val > 180) val = 180;

output += (val << (i * 8)); // stores val in the last 8 bits, then the next 8 bits to the left, and so on.

}

bool sent = radio.write(&output, sizeof(output)); // send output

if(!sent)Serial.println(“message did not send”);

}else{

long startMillis = millis();

while(!radio.available()){

if(millis() – startMillis > 2000){

Serial.println(“message timed out”);

return;

}

}

unsigned long input = 0;

radio.read(&input, sizeof(input)); // records the message in the variable input

for(int i = 0; i < numServos; i ++){

int val = ((long)0xFF << i * 8 & input) >> i * 8; // gets last 8 bits, then the next 8 bits to the left, and so on.

// rotates the servo, and throttles speed

int count = 0;

if(val > servoAngle[i]) count = increment; // count is positive if val > servo’s current angle

if(val < servoAngle[i]) count = -increment; // count is negative if val < servo’s current angle

if(val == servoAngle)continue; // servo has reached the desired angle, continue to the next servo

servoAngle[i] += count;

servos[i].write(servoAngle[i]); // update servo angle

}

}

if(!radio.isChipConnected())Serial.println(“chip not connected”);

delay(50);

}

void setAsWriter(){

radio.openWritingPipe(pipeAddress);

radio.stopListening();

}

void setAsReader(){

radio.openReadingPipe(0, pipeAddress);

radio.startListening();

for(int i = 0; i < numServos; i ++){

servos[i].attach(servoPins[i]);

}

}

Second Milestone

#include <Servo.h>

const int numServos = 4;

const int measurementPins[] = {A0, A1, A2, A3}; // pins to connect to the flex sensors

const int resistanceRangeA[] = {530, 510, 575, 530};

const int resistanceRangeB[] = {770, 650, 740, 670};

int increment = 5; // rate at which to move the servos – increment° / 50 millis

const Servo servos[numServos]; // creates the array of servo controller objects

const int servoPins[] = {5, 6, 9, 10}; // pins to attach to the servos

// 5 : ring/pinky, 6: middle finger, 9: index finger, 10: thumb

int servoAngle[] = {0, 0, 0, 0}; // stores the current angle of the servos

int increment = 2; // rate at which to move the servos – increment° / 50 millis

void setup() {

Serial.begin(9600); // for debugging

for(int i = 0; i < numServos; i ++){ // attaches pins and rotates servos to 0° position

servos[i].attach(servoPins[i]);

servos[i].write(0);

}

}

void loop() {

for(int i = 0; i < numServos; i++){ // for each servo

int val = analogRead(measurementPins[i]); // read from a flex sensor

val = map(val, resistanceRangeA[i], resistanceRangeB[i], 0, 180) / (2 * increment); // maps raw output to servo rotation, rounded to reduce twitching

val *= 2 * increment;

// makes sure val is in the correct range

if(val < 0) val = 0;

if(val > 180) val = 180;

// rotates the servo, and throttles speed

int count = 0;

if(val > servoAngle[i]) count = increment; // count is positive if val > servo’s current angle

if(val < servoAngle[i]) count = -increment; // count is negative if val < servo’s current angle

if(val == servoAngle)continue; // servo has reached the desired angle, continue to the next iteration

servos[i].write(servoAngle[i] += count); // update servo angle and turns the servo

}

delay(50); // wait 50 milliseconds before checking the flex sensors again.

}