Melanie A.

Hi, my name is Melanie and I’m a rising senior at Lyons Community School. My intensive project, a smartwatch, was inspired by this instructable. I chose this project because I’ve gained an interest in wearable technology, and I wanted to work on a project that combined programming, electronics, and creativity.

Overall, I had an enriching experience at BlueStamp Engineering. Not only did I obtain new skills I will use later in my career as an engineer, but I also learned a lot about myself. BlueStamp taught me that I can be humble while practing self-advocacy. I also realize the importance of amplifying my voice in a field where few resemble me and my perspectives.

My next step in my project is to make it solar powered and continue adding on more features.

Engineer

Melanie A.

Area of Interest

Mechanical Engineering,

Robotics Engineering,

Computer Programming

School

Lyons Community School

Grade

Incoming Senior

Final Project

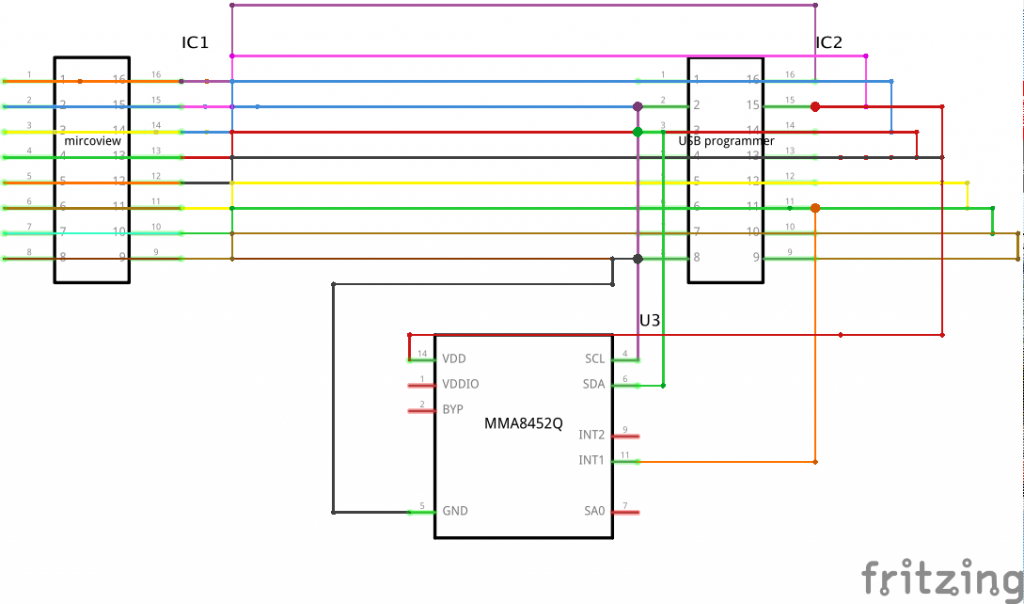

My first step was to draw some sketches of what I wanted my watch to look like. Next, I downloaded Autodesk Fusion, which is a CAD or Computer -Aided Design software. This is what I used to design my watch base. Then, I took all the necessary measurements to allow the watch to fit on my wrist and hold the microview and USB programmer properly. I used a calliper to measure the dimensions of my wrist, the microview screen, and the USB programmer. I made sure to leave some extra room for accelerometer, battery, and wires that will go underneath. After I completely finished designing the watch base, I had it 3D printed, I soldered the accelerometer and buttons to the USB programmer, and I made a velcro bracket to adjust the fit.

The most challenging part was designing a that would allow me to insert both the microview and the USB programmer. That is why I designed it so that the microview is inserted from the top of the watch and the USB programmer comes in from the bottom.

The skills I have obtained from completing this milestone was is designing projects using CAD and using a calliper.

Documentation

Here are my Fritzing schematics, CAD screenshots, GitHub code, and Bill of Materials.