Auto-Balancing Segway

The Auto-Balancing Segway is able to keep itself upright at all times, even when the robot is manually pushed

Engineer

Leo S.

Area of Interest

Mechanical Engineering

School

Lynbrook High School

Grade

Rising Senior

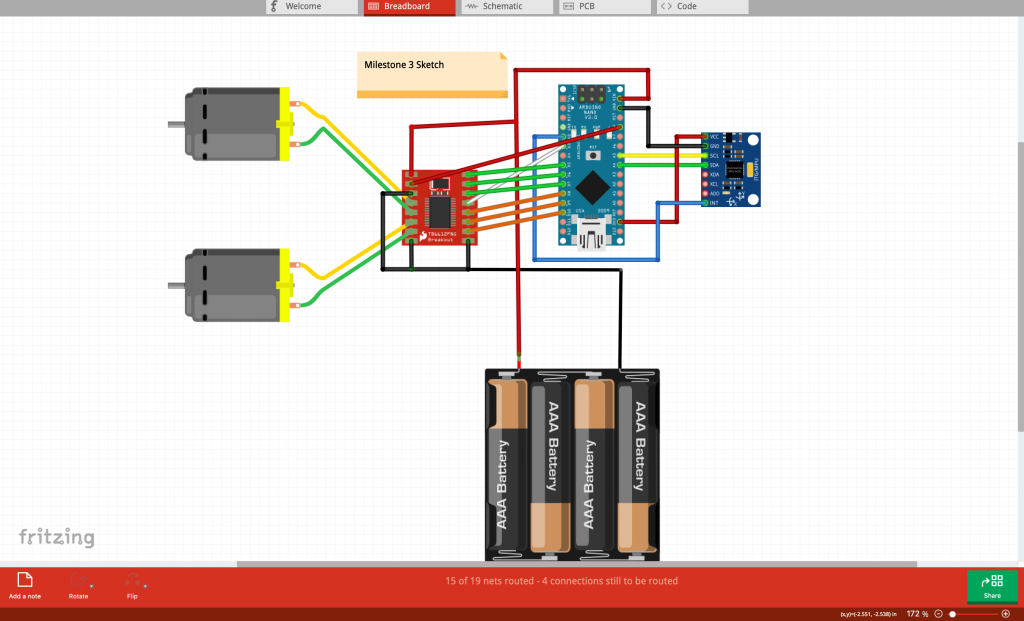

Final Milestone

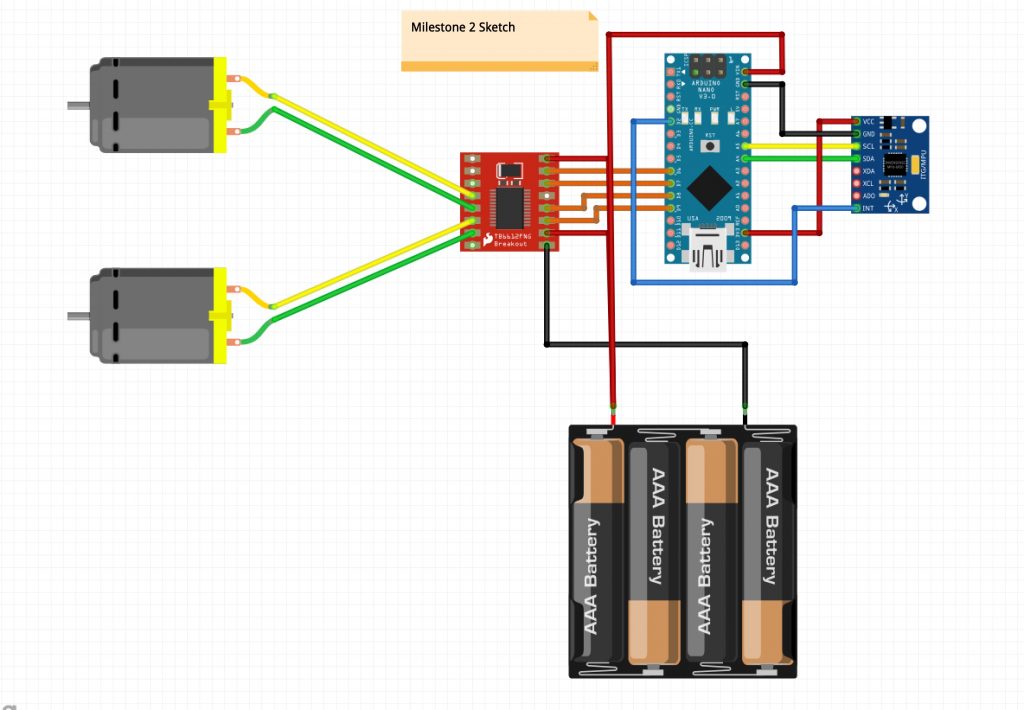

Second Milestone

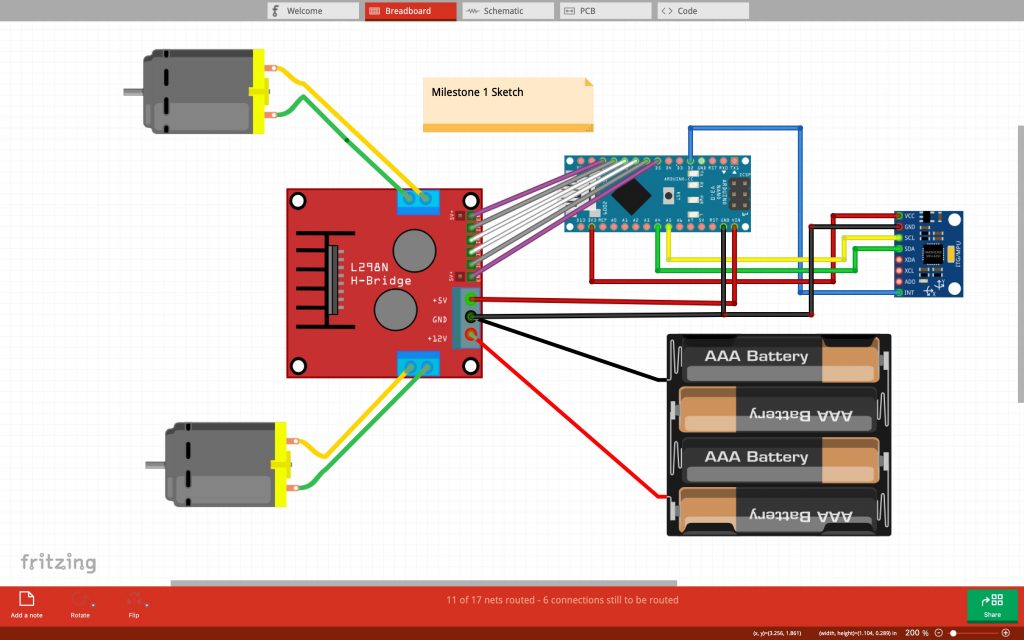

First Milestone