Final Milestone

With my final milestone, I tried to clean up the design and “finalize” the project. I did this with paint, a better handle and more quality assembly. I also described some upgrades I was planning on doing if I had more time. One of these is a dial that would control the pitch of the tone coming out of the speakers. This would add a nice level of polish as well as making it easier to listen to. I would also like to add a button where the trigger of the water gun would be. I believe this would make it feel more natural to use.

Second Milestone

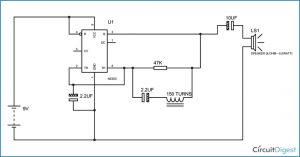

I have made lots of progress since my first milestone video. I haven’t made any changes to the actual circuit but instead, I built the chassis for the device. I first permanently mounted the breadboard in the electronics box. I lengthened the wires so it would reach all the way down the pipe, I installed the coil onto the bottom of the pipe, made a handle out of a water gun with the barrel cut off, and mounted it onto the pipe as well. For the future milestones, I plan to build a more effective button and add a potentiometer so the tone can be changed.

First Milestone

TV-B-Gone Starter Project

For my starter project, I selected the TV-B-Gone. This device is used to turn off any TV that has an IR receiver. I soldered all the components to their required spots and assembled the parts together. In the end, it was not the building that was the most difficult but the explaining. I had to do lots of research in order for me to fully understand how all the parts worked together. Now I am able to explain what happens from when you press the button to the LEDs firing. When you first press the button, it resets the IC. When the IC resets, it uses its internal 8mhz timer to send a signal out to the first transistor. That transistor than uses its own much more robust timer to regulate and send voltage to the four IR LEDs. These LEDs then light up at the frequencies that are most common for different TVs. The blue LEDs are for more concentrated beams and the white LEDs are for wider beams.