3D Printed Robotic Hand

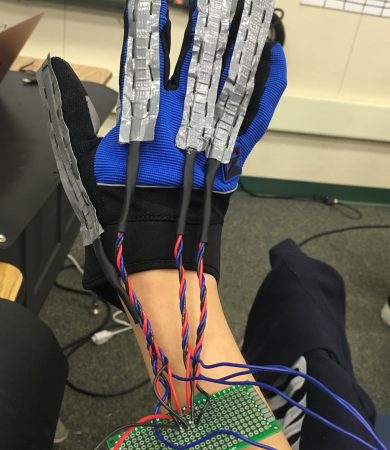

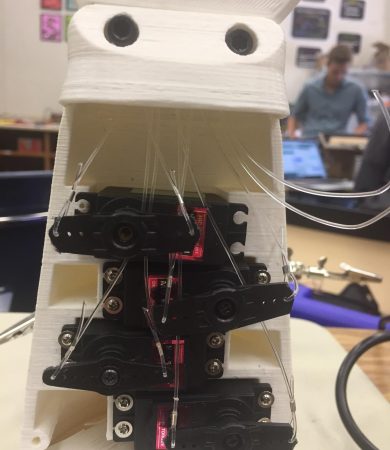

This wirelessly-controlled, 3D printed robotic hand mimics the movements of a glove on the user’s own hand.

Engineer

Annabel Y.

Area of Interest

Bioengineering

School

UC Berkeley

Year

Freshman

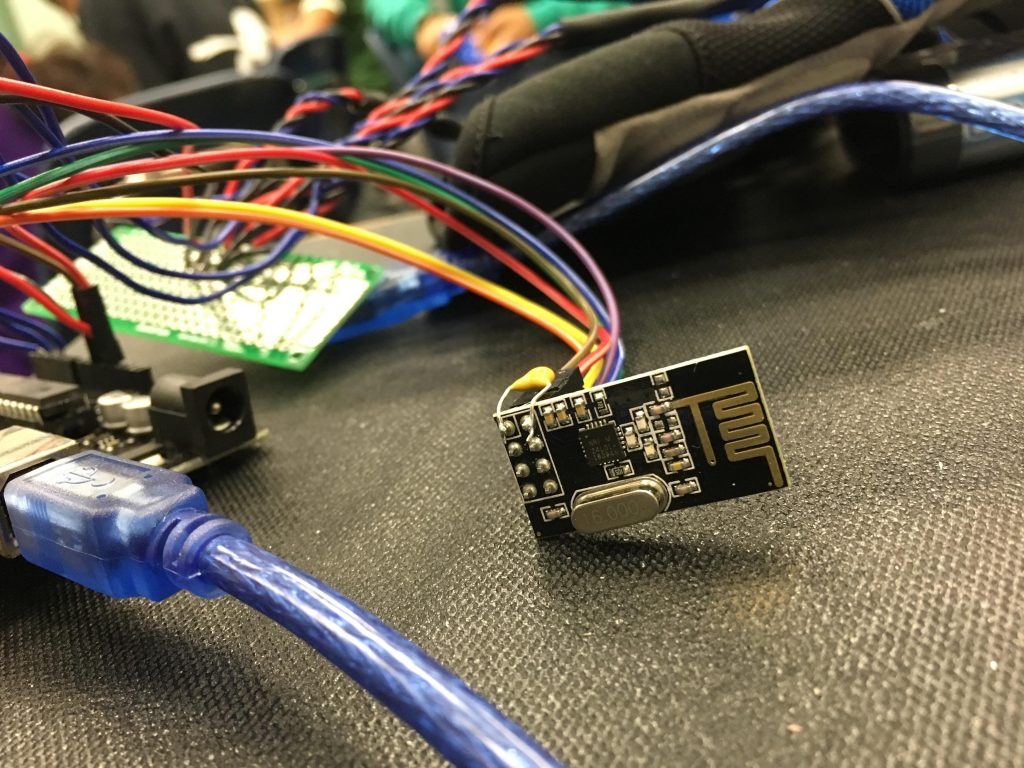

Reflection

Coming into BlueStamp, I had very little engineering experience. However, at the end of this journey I have come out with a greater understanding of how to problem solve and troubleshoot as well as an insight into the kind of engineering I want to pursue. At BlueStamp, I learned to be independent; most of the problems I encountered could be solved by the internet and I learned a great deal through first-hand experience and trial and error. Blowing up servomotors and re-threading fishing line were challenges that lent themselves to reflection, re-evaluation, and modification. In addition, encountering so many different kinds of engineering sparked my interest in areas I had not entertained before. For example, computer science used to be my least favorite subject, however, the challenge of coding the wireless nRF modules became my favorite part of the project. Also, my intended major is bioengineering, but after talking to various experts in the industry, I am considering pursuing mechanical engineering and industrial design instead. Overall, BlueStamp has taught me how gloriously frustrating and difficult engineering can be, but also how incredibly rewarding it can be to struggle, persevere, and finally conquer the challenges ahead.

Below is the final presentation of my project:

You can access my code, bill of materials, and helpful links in Google Drive.

Final Milestone

Second Milestone

First Milestone

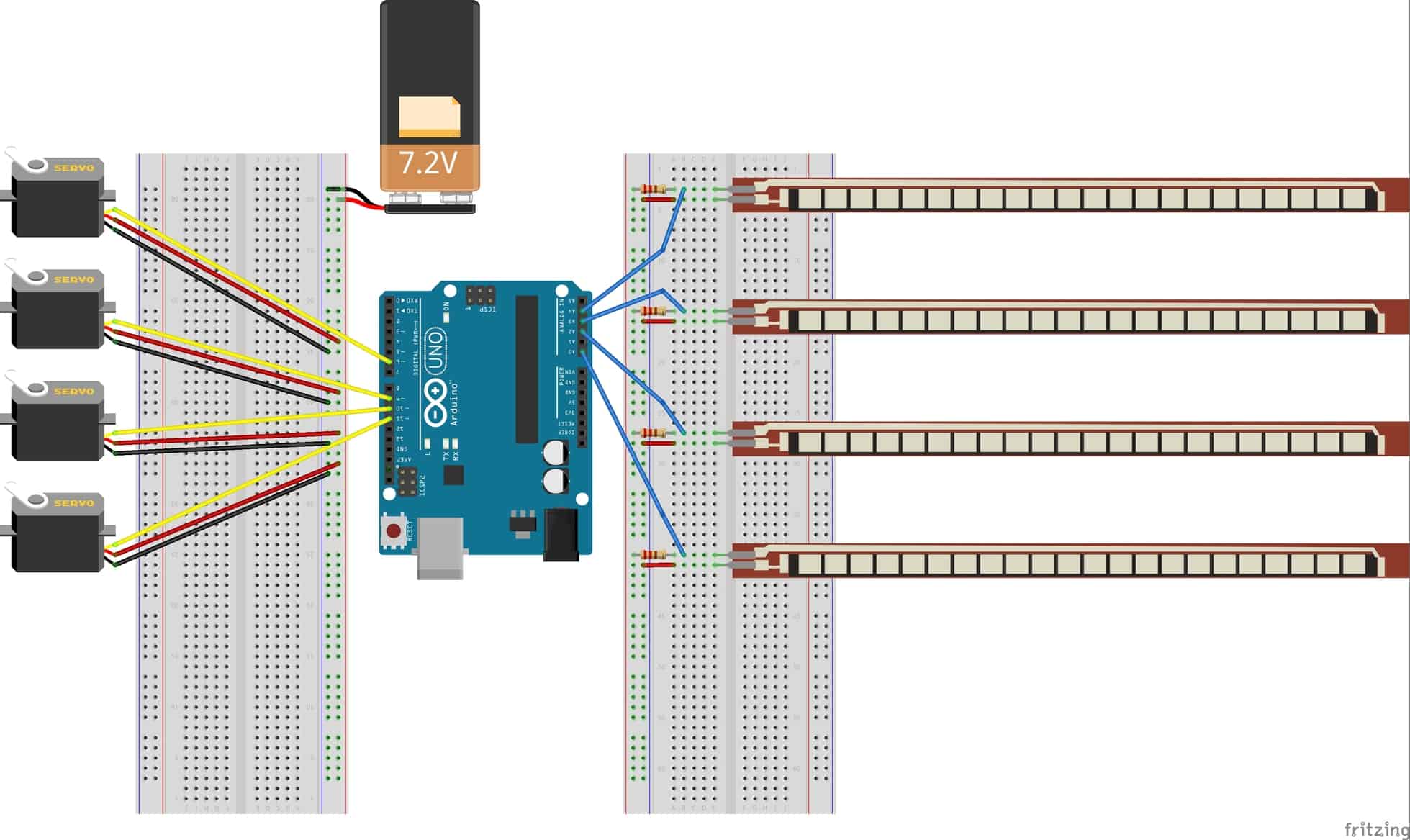

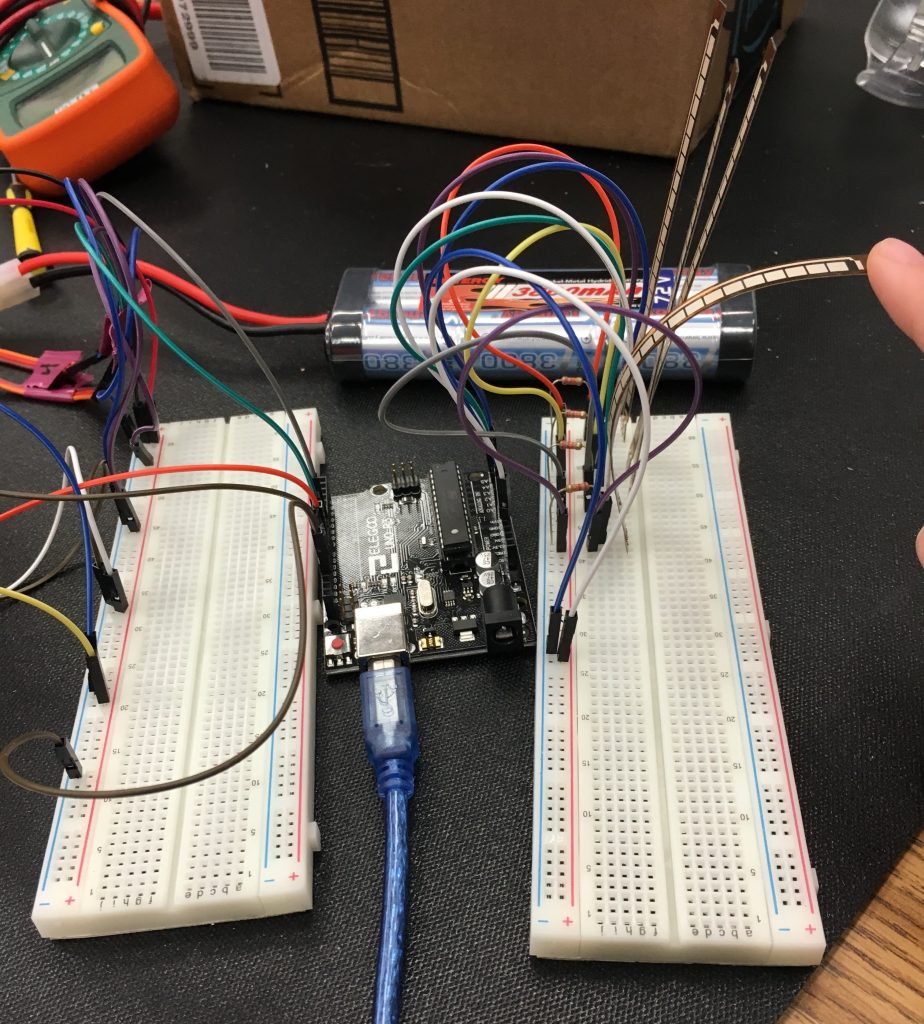

I based my schematic off of one designed by a previous BlueStamp student.