RC Hovercraft

A remote controlled craft that can lift off the ground and move around. Think of a hoverboard that actually hovers. Made from cut foam, tent fabric, and a whole lot of glue and tape. Electronics are stuffed into the center compartment. and controlled with a FlySky FST6 Radio Controller and reciever.

Engineer

Richard F.

Area of Interest

Aerospace Engineering

School

Leland High School

Grade

Incoming

Sophomore

Reflection

Bluestamp has taught me more than simple skills like soldering and electrical engineering concepts. I’ve learned to manage my time efficiently and set goals for myself every day I’m here. In addition, we keep a “journal” of sorts to track our progress throughout the 6 weeks. I’m given a lot of time to do independent work and the mentors are there mostly to guide us to the correct answer rather than give us the answer or act like a teacher. It’s so much more different than an engineering class at school, and the skills I’ve learned will help me in my future projects and modifications. Mostly, I will take this knowledge back to my robotics team so I can gain a larger presence on the team mechanical and engineering side.

Showcase Night

Second Milestone

Hovercraft Assembly

First Milestone

Video explaining Brushless Motors

Video explaining circuit connections for the hovercraft

Video explaining RC radio system

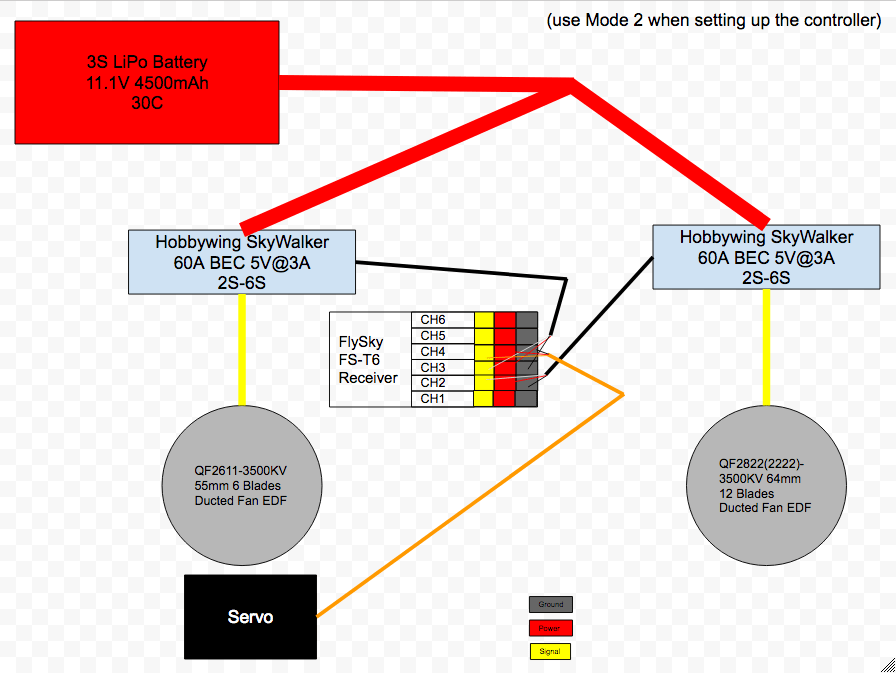

Circuit Diagram