Smart Lamp with IoT Technology

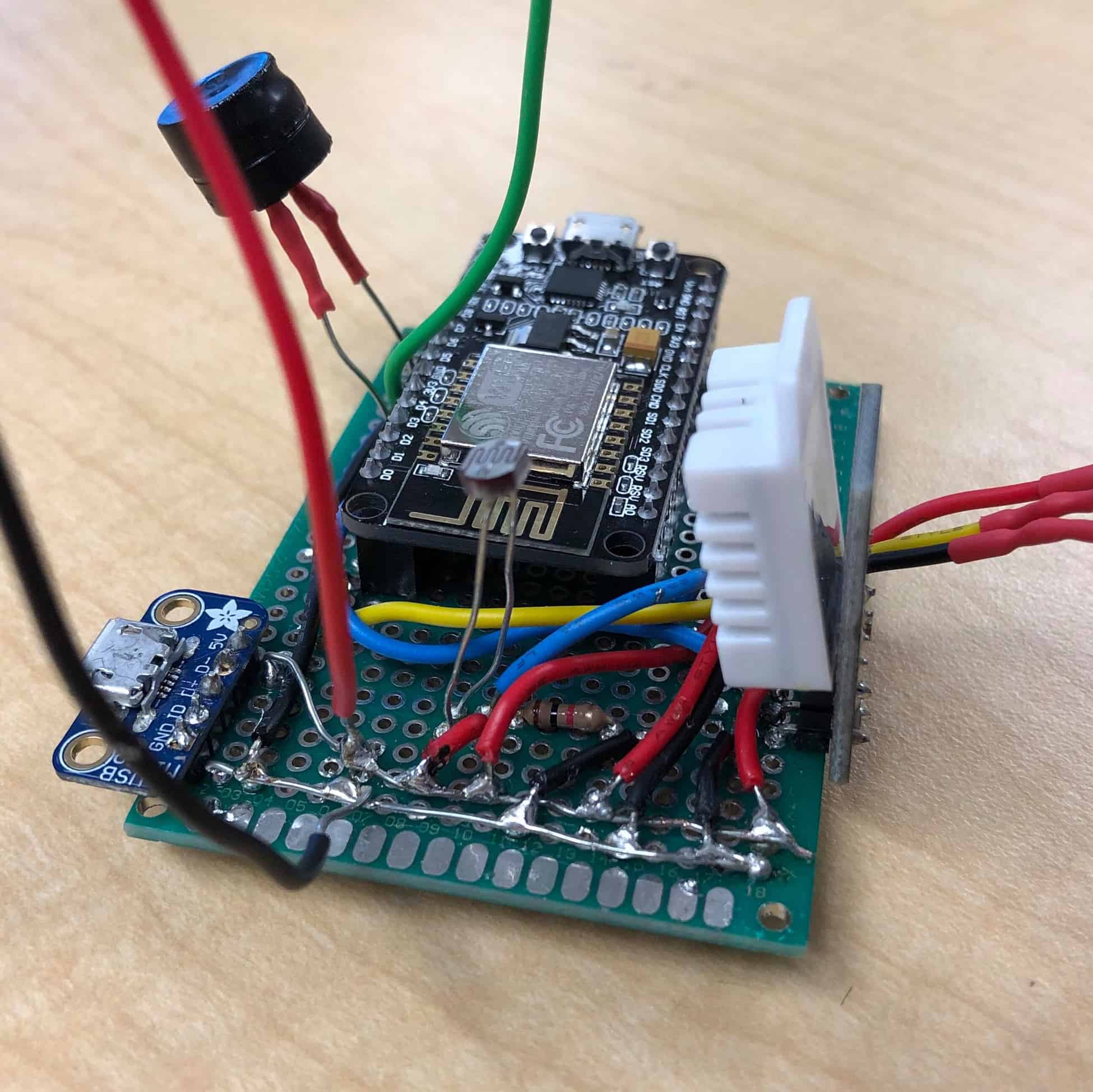

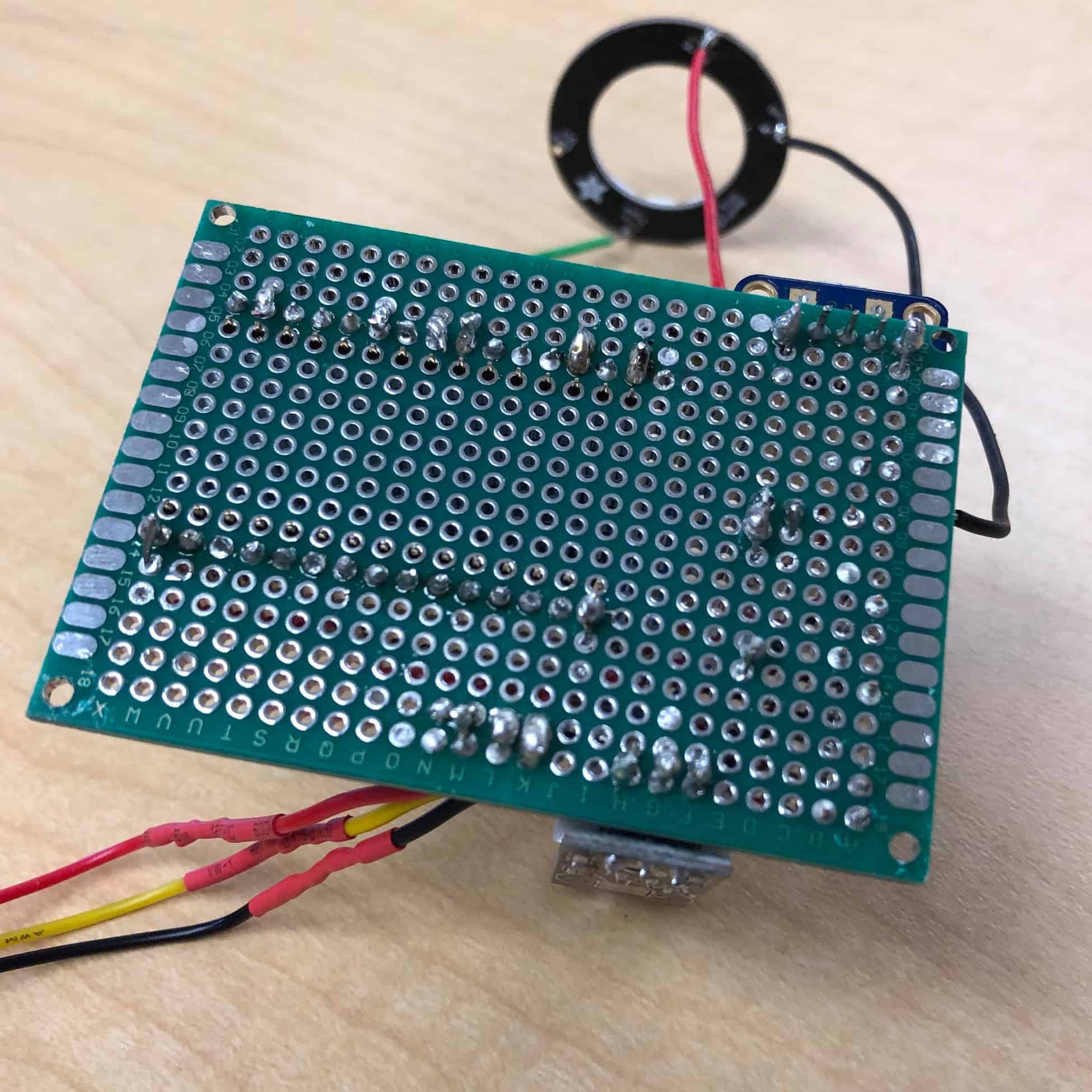

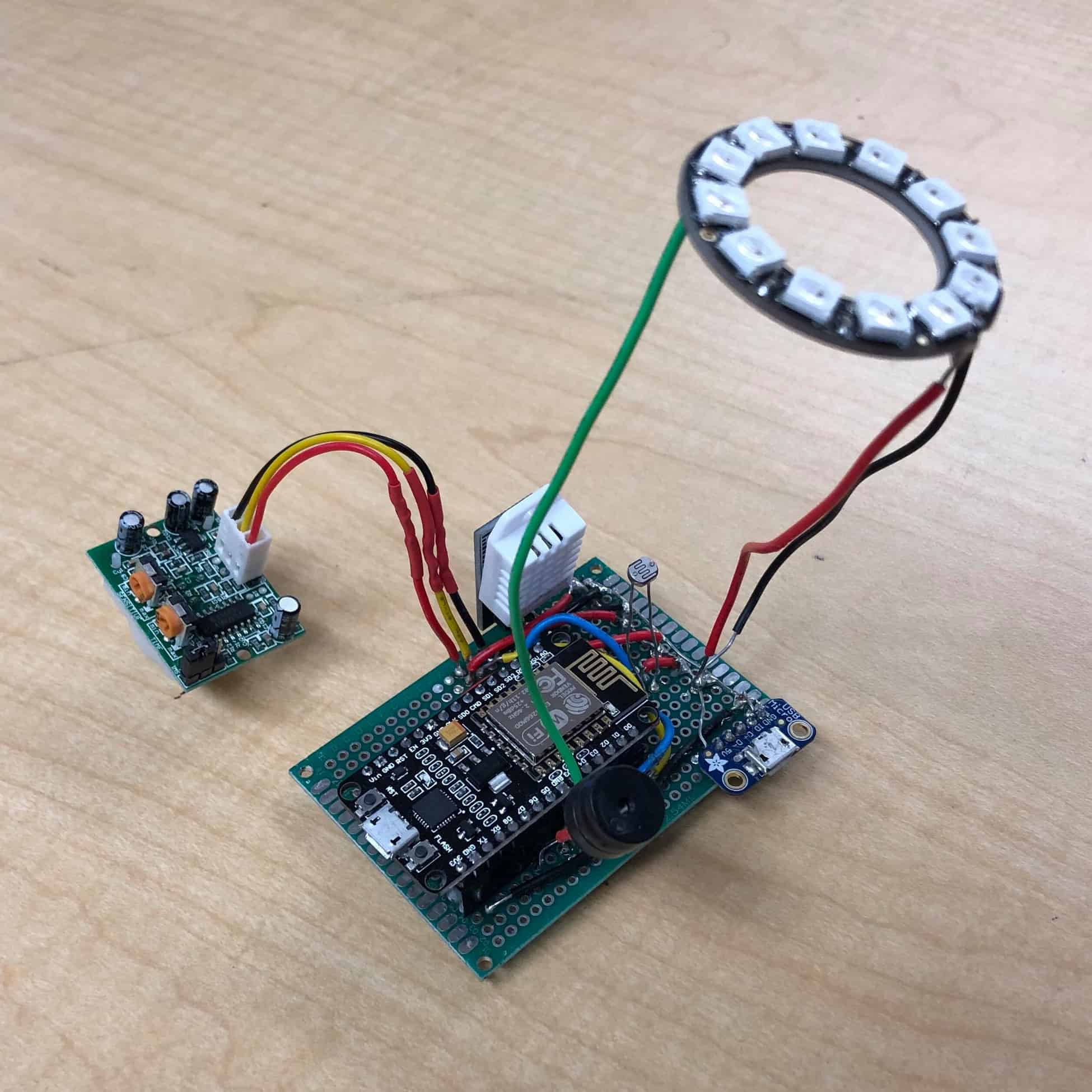

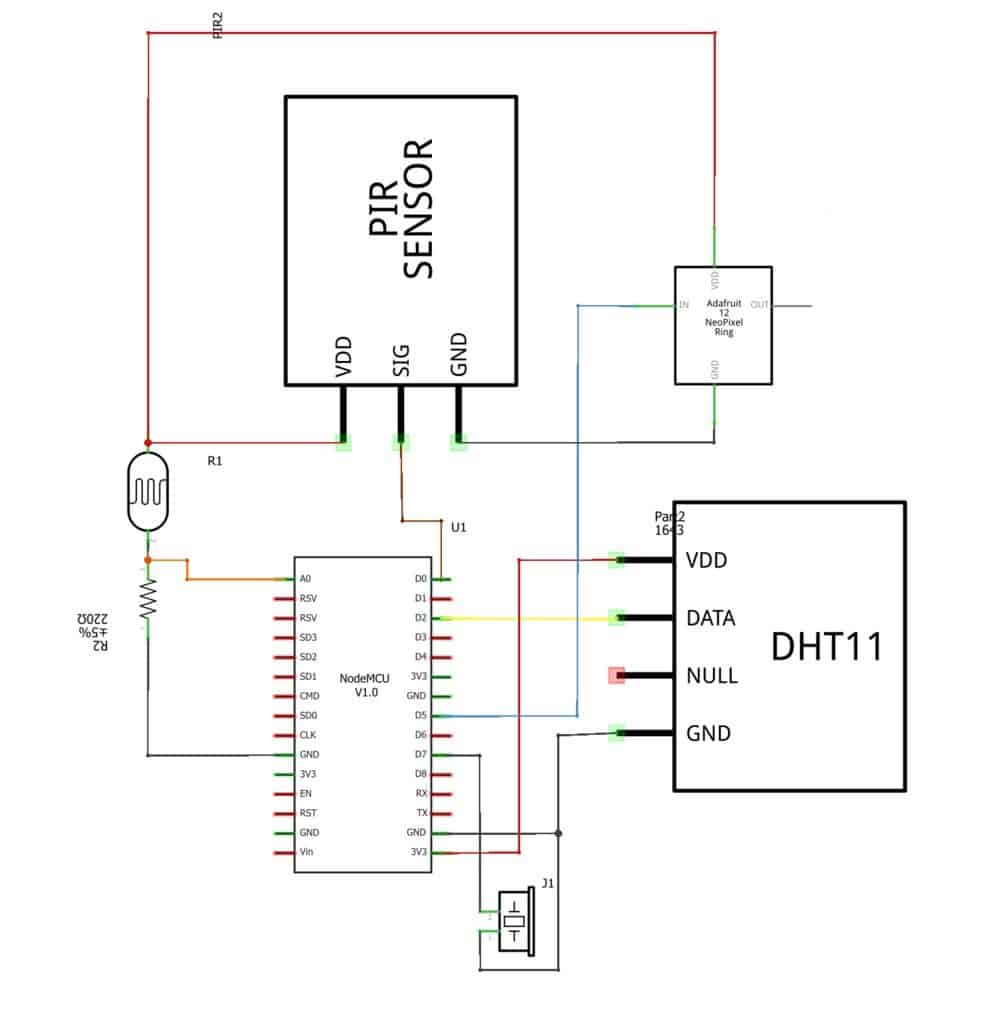

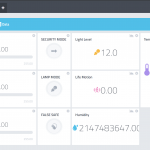

A fully color-customizable smart light with sensors that detect environmental parameters using IoT technology.

Engineer

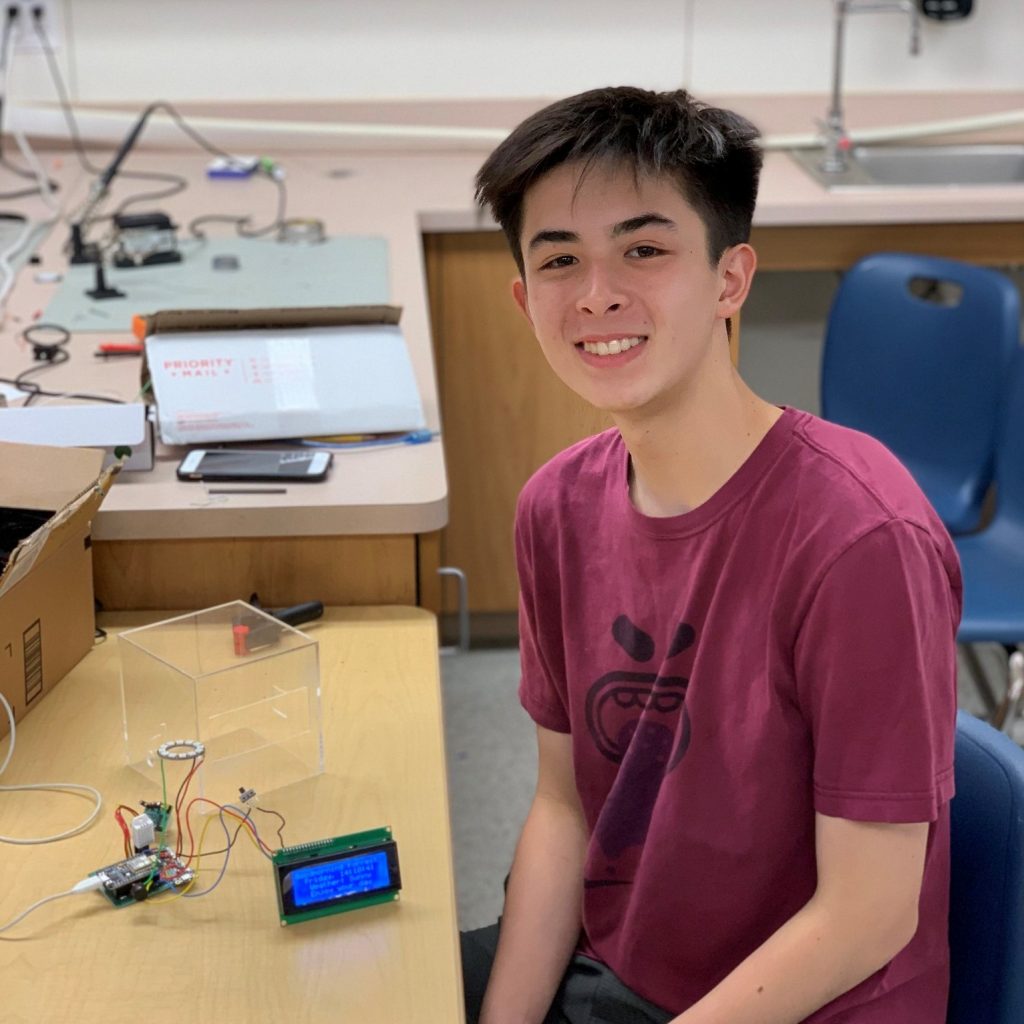

Forrest L

Area of Interest

Computational Finance

School

Monta Vista

Grade

Incoming Senior

Reflection

During my six weeks at Bluestamp Engineering, I learned a lot of skills that I never would have the opportunity to learn in a classroom setting, which include coding with the Arduino IDE, dremeling, soldering, and much more! Most importantly, I gained a newfound interest in mechatronic and electrical engineering, and hope to further pursue it by building passion projects in my free time.

As for my project, I plan to further add more features to my LCD fixture. I will add a button to the top of the box that will allow for me to call a new display screen to display on the LCD that has new widgets, such as customized stocks and calendar events.

Final Milestone + Modifications