DIY Fitbit

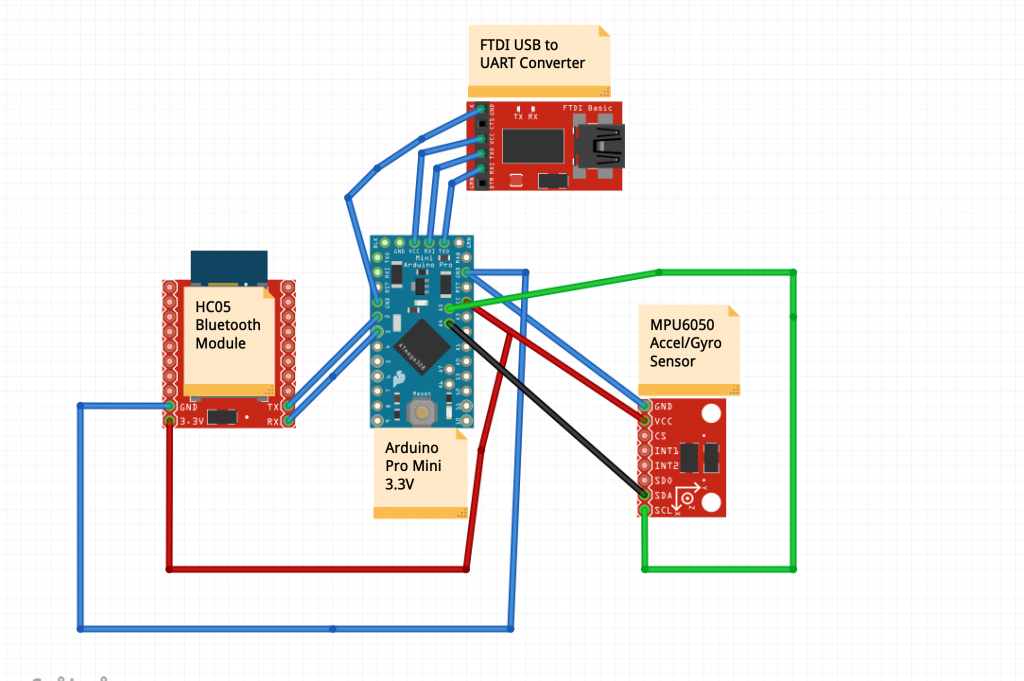

Fitbits are extremely useful wearable devices that can be used to monitor steps and calories burned. This DIY Fitbit utilizes Arduino and reports data in an iPhone mobile app to be viewed.

Engineer

Shashwat M.

Areas of Interest

Engineering, Biotech, Finance

School

American High School

Grade

Incoming Senior

Final Project

Second Milestone

First Milestone